FREE DELIVERY FOR WELDING*

* On Business Days - Purchases $100 or More

2.5% OFF By paying with Check, Wire or ACH

Online and Call-Ahead Orders

* Minimal Purchase Price $100

Andrew Piispanen

-

April 30, 2021

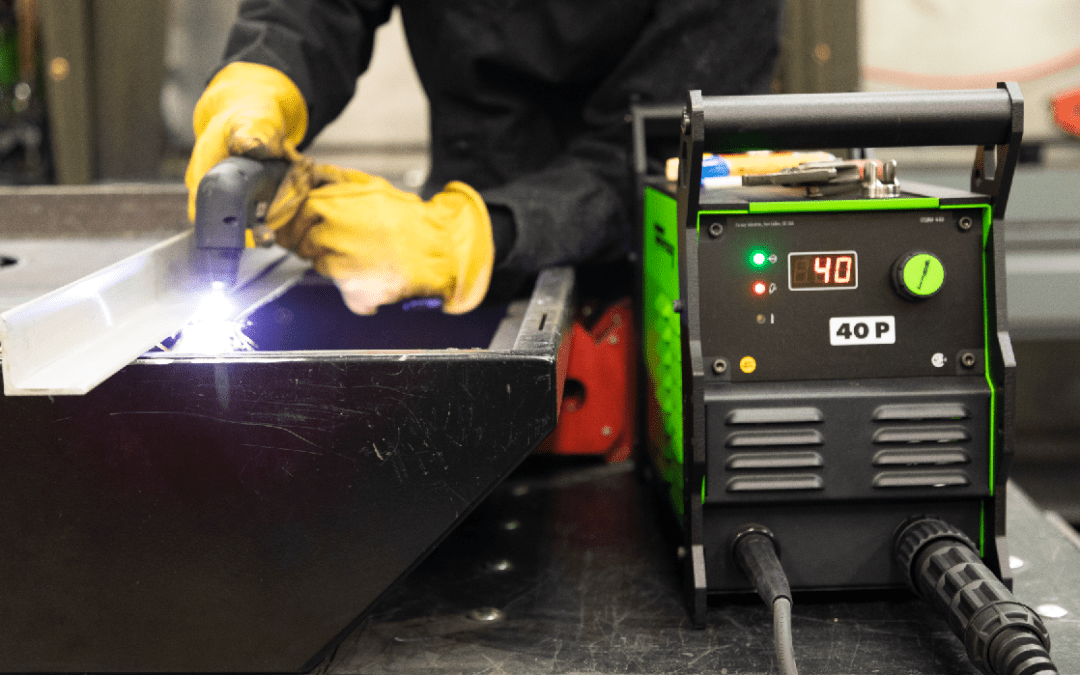

Plasma cutting is a concept many of us know to be fast, easy to work with and efficient, but what really goes into plasma cutting - and why are they so popular?

-

April 13, 2021

There are various options available when selecting a metal cutting saw for your project. Not only will the right saw make you more efficient and productive, but will also save you a great deal of money that would otherwise be spent on repairs.

-

February 12, 2021

Multiprocess welders combine both plasma TIG and Stick welding - but how does plasma get so hot, and how does it really melt metal?

-

January 15, 2021

Bandsaws come in many shapes and sizes - but most sizes aren't made equal. A lot of companies that we work with often don't know exactly what they're looking for, and overlook some of the important differentiators between sawing types. Here we'll give a brief overview of those 2 sawing types:

-

December 03, 2020

There are obvious costs in used equipment that many businesses forget to realize when they purchase them. We'll explain a few hidden costs that make a compelling case for buying new machinery as opposed to used - and yes, we are biased.

-

November 06, 2020

We've all seen them crush things on Youtube. However, in most of metal manufacturing, not all presses are made equal. Taking on Dake's hydraulic presses, we'll see the different types of hydraulic presses.

-

October 19, 2020

There are many different types of bandsaws on the market. Some cut metal, others saw wood and depending on the use - some are even designed to saw through meat! When you're buying a bandsaw and trying to decide which one is right for you, here are some important things to consider:

-

September 24, 2020

Each of the four welders above has its pros and cons and are uniquely suited for particular welding jobs. Here is a comparison of the four welding types and the metals they are suited for working on.

-

August 27, 2020

With much uncertainty and even bits of chaos in the manufacturing industry, there are many doubts about the future of manufacturing in America. The potential of digital advertising and online business has skyrocketed globally, as new strategies for companies to reach their customers have made a tremendous opportunity in industry. On top of this, new supply chain disruptions have made operations managers rethink what the word “international” truly means. In the machinery market, there have been many setbacks and delays due to both regulations and to slower productivity.

-

May 22, 2020

MIG welding involves continuous use of a consumable electrode which produces a spark in the gun. This spark melts the surface and allows the surfaces to be joined, creating the weld.

TIG, on the other hand, involves passing a current through a non-consumable electrode to join the metal surfaces.

However, when choosing between the two there are several factors to consider.