FREE DELIVERY FOR WELDING*

* On Business Days - Purchases $100 or More

2.5% OFF By paying with Check, Wire or ACH

Online and Call-Ahead Orders

* Minimal Purchase Price $100

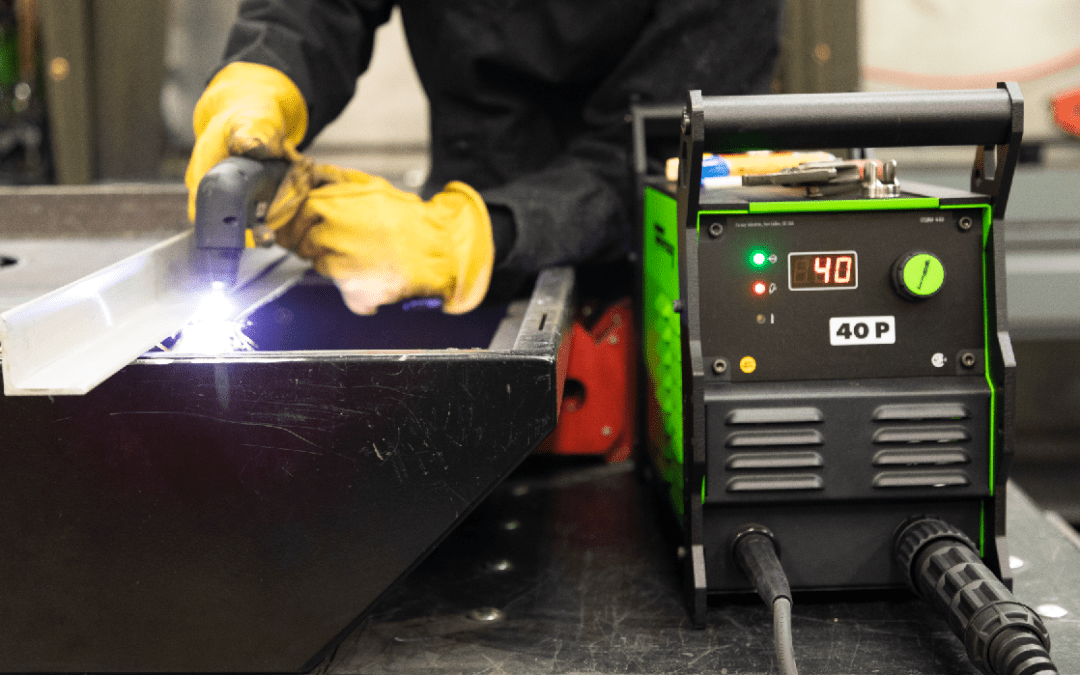

Plasma Cutting Machines

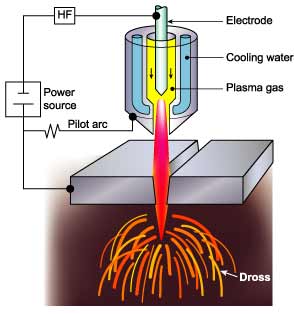

Multiprocess welders combine both plasma TIG and Stick welding - but how does plasma get so hot, and how does it really melt metal?

Plasma cutting machines – hotter than the sun

Plasma cutting is hot – so hot, that it is 4 times the heat of the sun’s surface. At almost 40,000 degrees F, plasma cutting is a melting process that involves both an electric current and a gas. Although plasma cutters may look similar to welding machines, their purpose can be very different. For cutting metal, plasma is a great way to upgrade your manufacturing outlet.

Why is plasma so effective for cutting?

Plasma cutting is useful for the following reasons:

- Cost-effective, as units can be combined with welders to make multi-process welders

- Better speeds than sawing

- Higher accuracies than waterjet

- A wide variety of metals can be cut

Before we go into ways plasma cutting helps manufacturing, how does it get so hot?

The gas can be shop air, nitrogen, argon, or oxygen, and is pumped out at high speeds. The gas is pumped with an electric arc through a small opening at the tip of the torch, which can then cut through the molten metal. Because of its intense heat, the gas cuts seamlessly through the metal workpiece.

How does plasma stack up against other types of metal cutting?

Plasma cutting has significant advantages to other types of cutting. Other types of cutting, such as waterjet and sawing don’t always get the kinds of accuracy that certain plasma machines can get. Although it can be accurate, plasma cutting is good for being cost effective while fast. Some cutters can cut from 10 in/min to 160in/min, depending on the material. Plasma cutting can cut a wide variety of metals, and can produce accuracies that are better than 0.008”. They require simple maintenance, and are much more cost efficient than other forms of cutting, such as laser cutting. Recent advances in technology, too, have made holes better equipped, so cutting down into metal is much more feasible than it used to be. However, edge quality may be compromised, and in some industries, waterjets may do a better job here. As a result, grinding may be required to remove the burrs from the part.

How to determine cutting speeds

To determine cutting speed and thicknesses and speeds, the thickness of the material plays a direct relationship into the speed of the material, especially when you are looking for optimizing speed:

Are plasma cutters able to weld?

Unfortunately, plasma cutters do not weld well, unless they are purposely designed to. Typically, plasma cutting machine that also welds is called a “multi-process” welder, and has been increasingly popular in the last decade. Multi-process welding has 3 functions: TIG welding, plasma cutting, and stick welding. The best part of this machine is that it combines many tasks in one, and simplifies shops to make it more cost efficient to utilize all 3 functions. Many brands, such as Forney, Baileigh, Razorcut (by Jasic) and Thermal Dynamics sell plasma cutting devices in either multi-process or straight plasma cutting machines.

Where can I learn more about this?

To learn more about plasma cutting and multi-process welding, see below:

If you have any questions, please don’t hesitate to reach out to us at (781) 937-5655 or at [email protected]