FREE DELIVERY FOR WELDING*

* On Business Days - Purchases $100 or More

2.5% OFF By paying with Check, Wire or ACH

Online and Call-Ahead Orders

* Minimal Purchase Price $100

Horizontal vs. Vertical Bandsaws

Bandsaws come in many shapes and sizes - but most sizes aren't made equal. A lot of companies that we work with often don't know exactly what they're looking for, and overlook some of the important differentiators between sawing types. Here we'll give a brief overview of those 2 sawing types:

Pros and cons of a horizontal vs. a vertical band saw

Basic differences of bandsaws

The most basic difference is that horizontal bandsaws typically cut straight across, meaning that the cut will be square with your material. There is little room for customization, similar to using a high-powered hacksaw on your metal. Instead, vertical bandsawing is more intricate, and allows for much more detail to be applied to the material.

Vertical Bandsawing

With vertical sawing, the saw blade remains in a stationary position, allowing for the material being cut to be moved around the blade. The workpiece is fed though the blade, which allows for a higher customization for smaller parts. It can cut parts down to size, but this is typically recommended with a horizontal band saw.

Vertical bandsaws are best used with hobbyists and custom part manufacturers (automotive, aerospace, medical devices etc.). Depending on the production requirements, vertical saws can run anywhere from $300 for low production woodworking hobby shops to well over $50,000 if it requires high metal production for an operations floor.

The benefits of a vertical bandsaw include the following:

- The ability to work with small

- Many types of vertical bandsaws have great built-in features, such as:

- Air blowers to both keep the working blade cool and remove any dust from the work area.

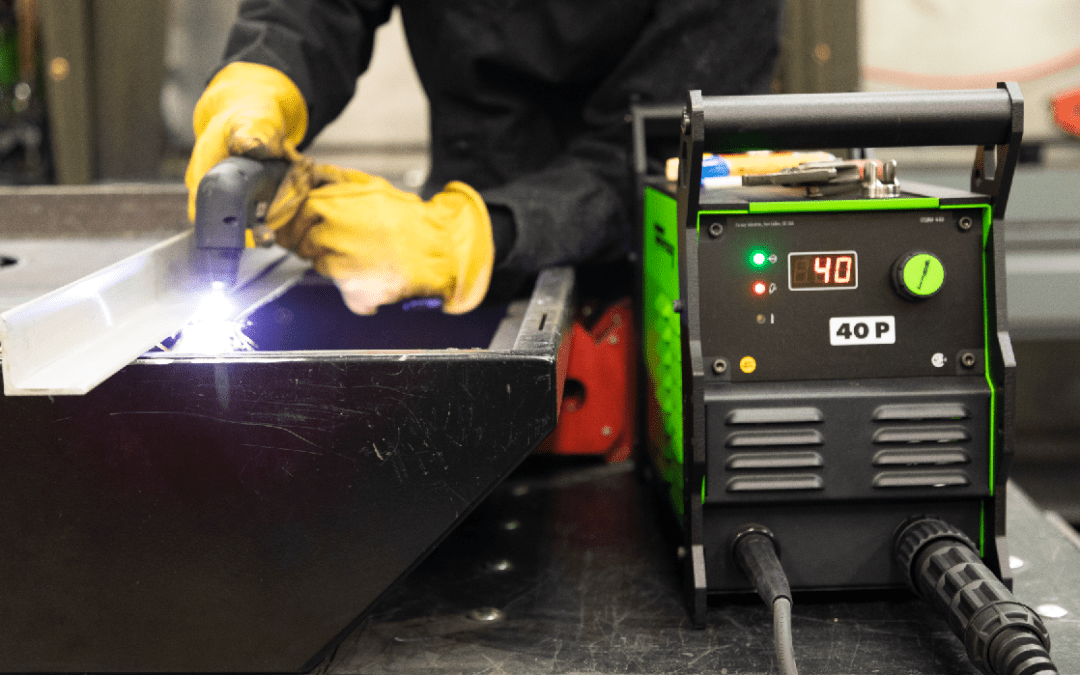

- Welders that can repair their own blades, build customized blades and repair parts

Setbacks include:

- Lack of precision due to the part not being set in one distinct place.

- More workplace risk that may result in injury, since the piece needs to be fed into the blade.

DoALL Saws are our specialty, as they sell high powered and high-quality sawing equipment for manufacturing:

New vertical bandsaws for sale at https://directmachines.com/manufacturers/doall.html

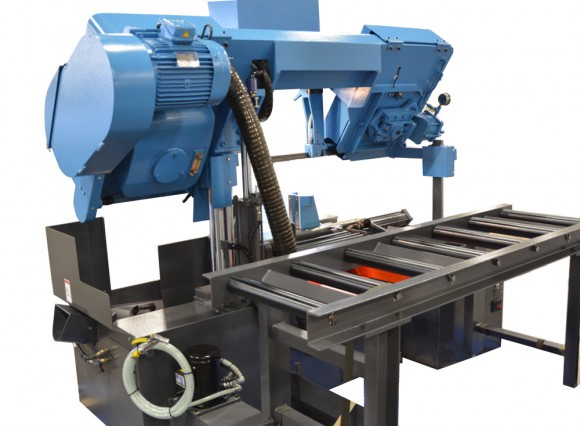

Hoizontal Bandsawing

With horizontal cutting, the blade is swung into the part being cut. It allows for greater precision and the ability to cut down sizes and sections of the material. For sheet metal, horizontal bandsaws are a great choice to cut down sheets to size.

Horizontal cutting machines can range widely in pricing. For small bandsaws, it can be around $400, but for horizontal, high-production setups with automation, the prices can go well over $100k.

The benefits of horizontal bandsaws include:

- When performing a straight cut, these saws offer great precision

- Can cut a wider variety of material relative to vertical bandsawing

- Can be programmed to cut automatically, so human operation isn’t always needed

- Quieter, more accurate, and create less mess

Disadvantages of using a horizontal bandsaw are:

- Cannot do complicated parts such as curves or complex 3d dimensions.

- Typically, these machines are large and can take up a lot of space for smaller manufacturing outfits

DoALL Saws also sells horizontal saws, and their high production capabilities make it easy to

New horizontal bandsaws for sale at https://directmachines.com/manufacturers/doall.html

Interested in more cutting machinery?

Direct Machines sells industrial manufacturing machinery to areas all over the US, directly from manufacturers. If you have a particular manufacturing need, we are consultants who will help you find the machines and equipment you are looking for. Give us a call at 781-937-5655 or shoot us an email at [email protected] see for yourself how buying with Direct can save your business time and money.