FREE DELIVERY FOR WELDING*

* On Business Days - Purchases $100 or More

2.5% OFF By paying with Check, Wire or ACH

Online and Call-Ahead Orders

* Minimal Purchase Price $100

Machinery

-

September 08, 2021

Are there any major differences between plasma cutting and oxy-acetylene?

-

April 30, 2021

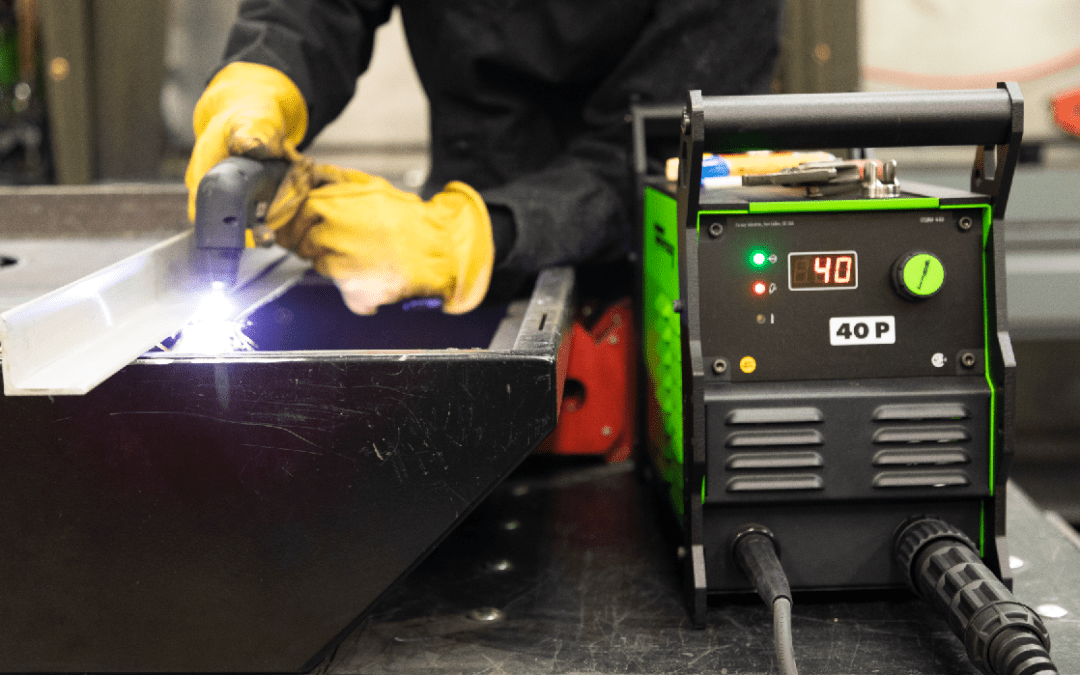

Plasma cutting is a concept many of us know to be fast, easy to work with and efficient, but what really goes into plasma cutting - and why are they so popular?

-

March 10, 2021

Ironworkers are widely considered one of the most useful machines in metal fabrication. It has become standard practice to have one in your shop - but why?

-

March 04, 2021

Milling can best be understood as drilling, but the “drill” moves sideways instead of straight up and down.

-

February 12, 2021

Multiprocess welders combine both plasma TIG and Stick welding - but how does plasma get so hot, and how does it really melt metal?

-

February 03, 2021

Grinders are useful tools for many different types of edging. For metal, edging is extra important, as it is a huge determinant of quality.

-

January 15, 2021

Bandsaws come in many shapes and sizes - but most sizes aren't made equal. A lot of companies that we work with often don't know exactly what they're looking for, and overlook some of the important differentiators between sawing types. Here we'll give a brief overview of those 2 sawing types:

-

December 03, 2020

There are obvious costs in used equipment that many businesses forget to realize when they purchase them. We'll explain a few hidden costs that make a compelling case for buying new machinery as opposed to used - and yes, we are biased.