FREE DELIVERY FOR WELDING*

* On Business Days - Purchases $100 or More

2.5% OFF By paying with Check, Wire or ACH

Online and Call-Ahead Orders

* Minimal Purchase Price $100

MIG vs. TIG Welding

The Differences of MIG vs. TIG Welding

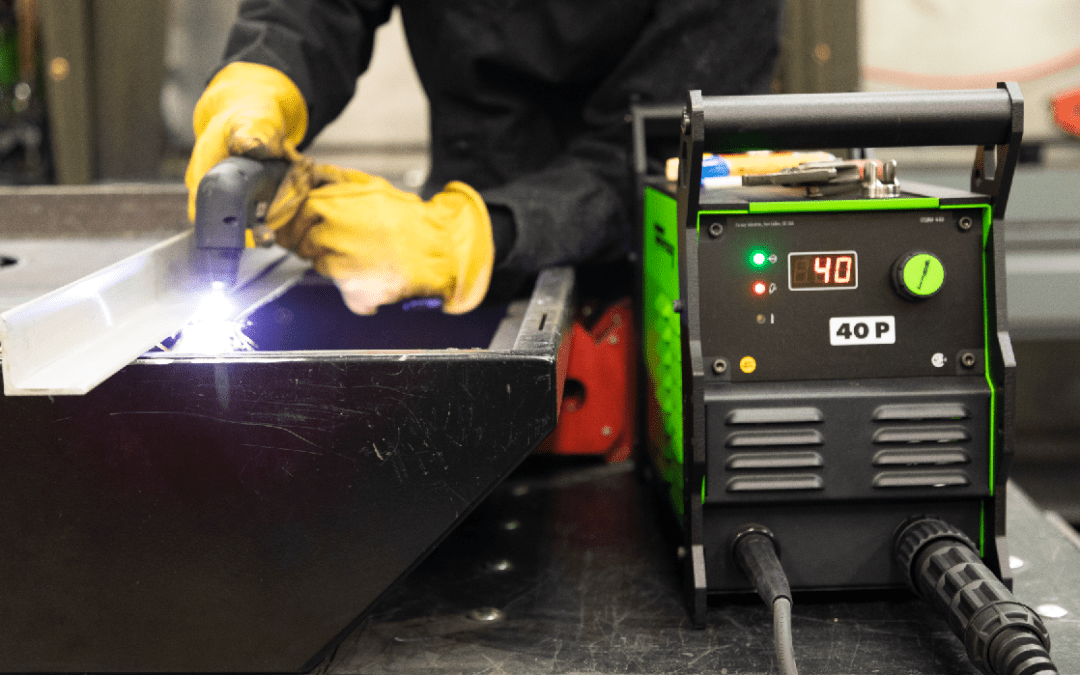

Metal inert gas (MIG) welding and tungsten inert gas (TIG) welding are both arc welding processes that uses heat from an electric arc to join two metallic materials together. They both require the use of an electric arc and operate with different modes which allows them to produce different outputs. In this article, we'll look at MIG vs. TIG welding.

MIG welding involves continuous use of a consumable electrode which produces a spark in the gun. This spark melts the surface and allows the surfaces to be joined, creating the weld.

TIG, on the other hand, involves passing a current through a non-consumable electrode to join the metal surfaces.

When questioning what type of welding process performs best for particular jobs, you must factor in your specific need and what you want your output to be. Below we will look at the factors that are considered when choosing the best welding process for your job.

Welding Considerations

When choosing between MIG and TIG welders, there are several factors to consider. These are:

Nature of Material

MIG and TIG welding can be applied to all metals. However, a TIG welder must have both alternating current and direct current in order to weld aluminum. TIG is best used for welding stainless steel. TIG uses a clean welding process since stainless steel has a thinner coat. Regular steel, on the other hand, can best be welded with MIG since steel can be easily burnt with MIG despite its dirtiness. The looks of the steel after is not usually taken into consideration as the steel is often coated after the machine operation.

Ease of Operation

In MIG welding, becoming a professional is quick and easy to learn. Unlike TIG, which requires multitasking with both hands and one foot, the MIG welding can be operated with one hand.

Speed and Quality

TIG welding is has a higher quality cut which is uses a longer process. The MIG welding, on the other hand, can be operated continuously with a faster travel speed than TIG. Large industrial companies more commmonly use MIG due to its fast pace which in result allows for high production rate.

Cost

In the manufacturing industry, time and money are directly related. Hence, it is safe to say that because TIG welding is a prolonged process, it implies that it is not cost-effective due to its higher price. MIG welding, on the other hand, costs less because the process is faster. MIG also does not require much preparation.

Furthermore, MIG is best suited for thick metals (26-gauge sheet metal to heavy-duty structural plates) because its wire feed acts both as an electrode and as filler. In result, energy is not wasted since the it does not take as long to bring the metal to its melting point. The filler also makes MIG the best choice for most welding processes.