FREE DELIVERY FOR WELDING*

* On Business Days - Purchases $100 or More

2.5% OFF By paying with Check, Wire or ACH

Online and Call-Ahead Orders

* Minimal Purchase Price $100

Cutting & Drilling

-

January 06, 2025

8 Common Reasons Your Metal Band Saw Isn’t Cutting Straight

Is your metal band saw failing to deliver straight cuts? Want to know what could be going wrong and how to fix it? You’re not alone! Your metal band saw is an essential tool in your operation, and when it fails to cut straight, it can disrupt your workflow and impact your product quality. Many metalworking professionals face challenges with band saws that don’t cut straight, impacting both efficiency and

-

September 08, 2021

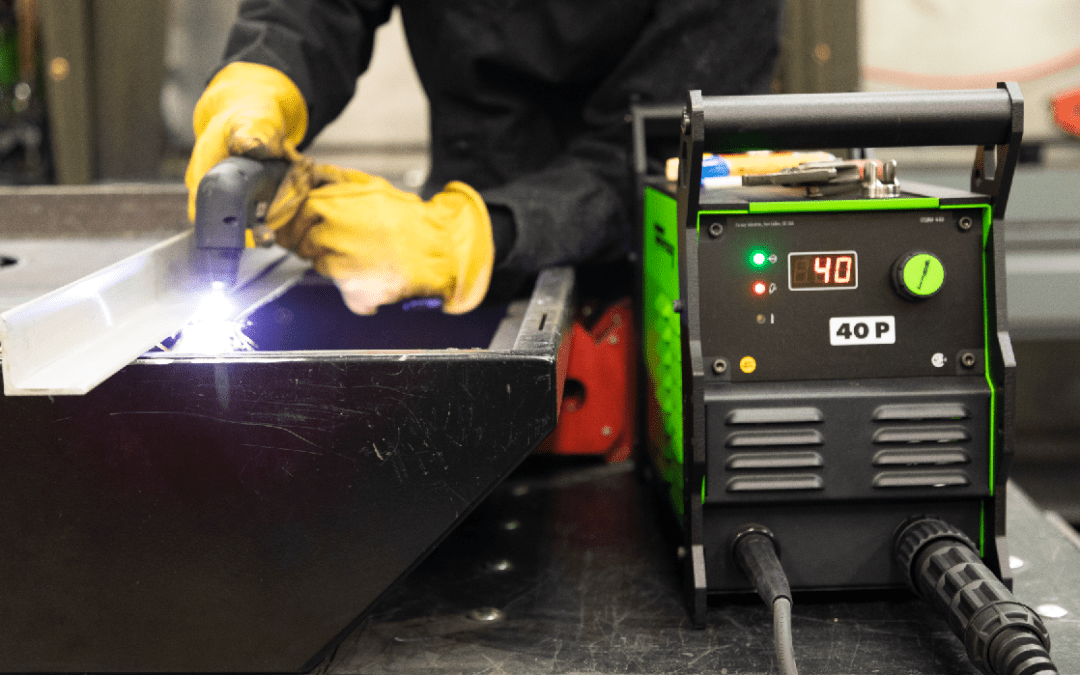

Are there any major differences between plasma cutting and oxy-acetylene?

-

April 30, 2021

Plasma cutting is a concept many of us know to be fast, easy to work with and efficient, but what really goes into plasma cutting - and why are they so popular?

-

April 13, 2021

There are various options available when selecting a metal cutting saw for your project. Not only will the right saw make you more efficient and productive, but will also save you a great deal of money that would otherwise be spent on repairs.

-

March 04, 2021

Milling can best be understood as drilling, but the “drill” moves sideways instead of straight up and down.

-

February 12, 2021

Multiprocess welders combine both plasma TIG and Stick welding - but how does plasma get so hot, and how does it really melt metal?

-

January 15, 2021

Bandsaws come in many shapes and sizes - but most sizes aren't made equal. A lot of companies that we work with often don't know exactly what they're looking for, and overlook some of the important differentiators between sawing types. Here we'll give a brief overview of those 2 sawing types:

-

October 19, 2020

There are many different types of bandsaws on the market. Some cut metal, others saw wood and depending on the use - some are even designed to saw through meat! When you're buying a bandsaw and trying to decide which one is right for you, here are some important things to consider:

-

July 08, 2020

Although it is essential for proper manufacturing, dust collection is usually overlooked as a priority. The importance of proper air filtration and waste handling can make the difference between a cleaned workspace and a hazardous one. Especially in a world where disease monitoring has become a part of workplace safety, proper ventilation and material handling is important for production to continue.

With that being said, there are many different types of ventilation systems for manufacturing, but in this article, we will define and explore 3 – wood dust collection, metal dust collection, and welding fume extraction.