FREE DELIVERY FOR WELDING*

* On Business Days - Purchases $100 or More

2.5% OFF By paying with Check, Wire or ACH

Online and Call-Ahead Orders

* Minimal Purchase Price $100

Plasma Cutting vs. Their Alternatives

Plasma cutting is a concept many of us know to be fast, easy to work with and efficient, but what really goes into plasma cutting - and why are they so popular?

What is Plasma Cutting?

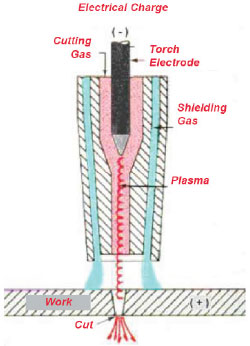

Plasma is an interesting concept. Plasma itself is one of the 4 fundamental states of matter, which consists of a gas of ions and free electrons. The way it is created is by heating a neutral gas or subjecting it to a strong magnetic field. Plasma cutters work by sending an electric arc through a gas through a constricted opening. The gas is primarily either shop air, nitrogen, argon or oxygen. The gas is pumped through the small opening at high speeds, which allows for it to cut through the molten metal. A shielding gas is used over the torch electrode and cutting gas in order to generate and then contain the plasma.

Since plasma is a separate state of matter than a solid, liquid or gas, it has different properties which make it unique. For one, the relative energy level in plasma is much higher than other states, as it is a high-energy ionized gas. With a plasma stream that transfers energy to a conductive work material, the heat of a plasma cutting arc can approach 40,000 degrees F, making it an effective tool to cut metal with.

How much does plasma cost?

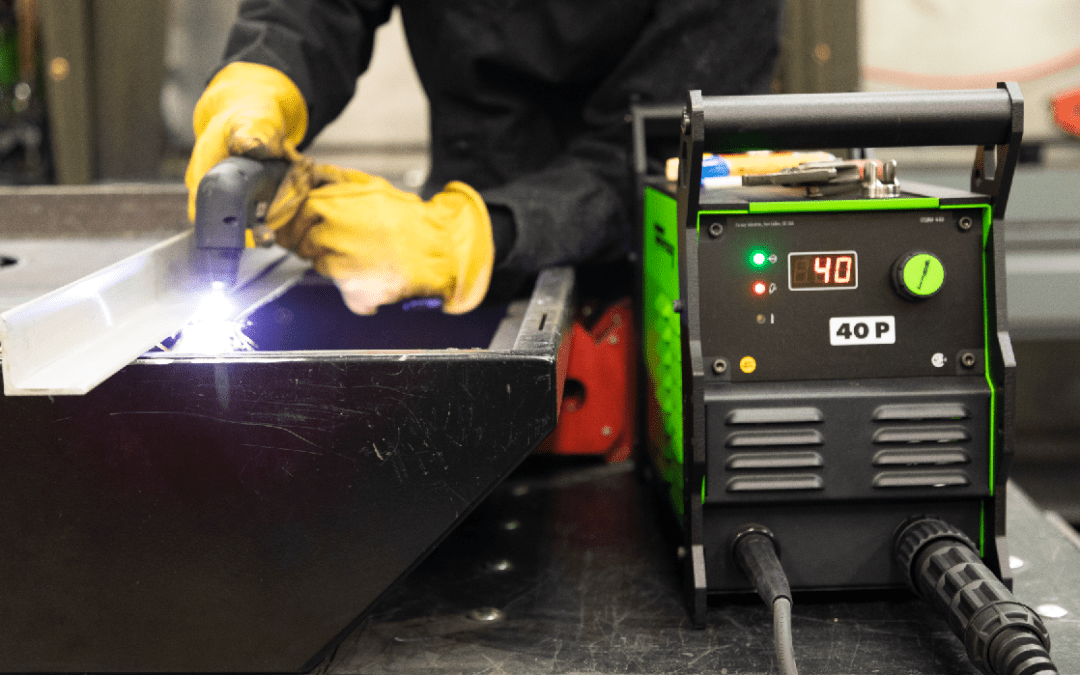

Even though the process of creating plasma to cut on conductive surfaces sounds complex, the technology is relatively cheaper. For one, plasma cuts fast and effectively, and with the exception of the nozzle itself, the rest of the requirements are cheap. Plasma tables can range from a few thousand to $300,000, while plasma cutting boxes can get as a low as a few hundred dollars. The reason why plasma cutting is so popular is mainly due to its value for the dollar – as it is both effective in terms of quality cuts while saving costs.

Compare to alternatives

Waterjet Cutting

Water cutting is useful when it comes to cost-efficiency on thicker plates. However, when it comes to small and fast cuts, plasma beats out water here by a large margin. Water jet cutting, however, does have a larger range of materials that it can cut through - including plastic, , whereas plasma should be used primarily for steel and other conductive materials. Water cuts clean with thick materials, but plasma will cut with advanced accuracies, of +/- .01” – .030”.

Fiber lasers

With Fiber lasers, the costs go up but so does the effectiveness of it. Fiber lasers are faster, stronger and more effective – but currently, they’re only targeted at large businesses. The costs required to purchase and work with fiber lasers is very capital-intensive, so unless you’re looking to spend hundreds of thousands of dollars, plasma cutting may be the best alternative here. However, if large fiber lasers do catch your interest, be sure to check out Carlson Fabrication Solutions' list of Mitsubishi fiber lasers.

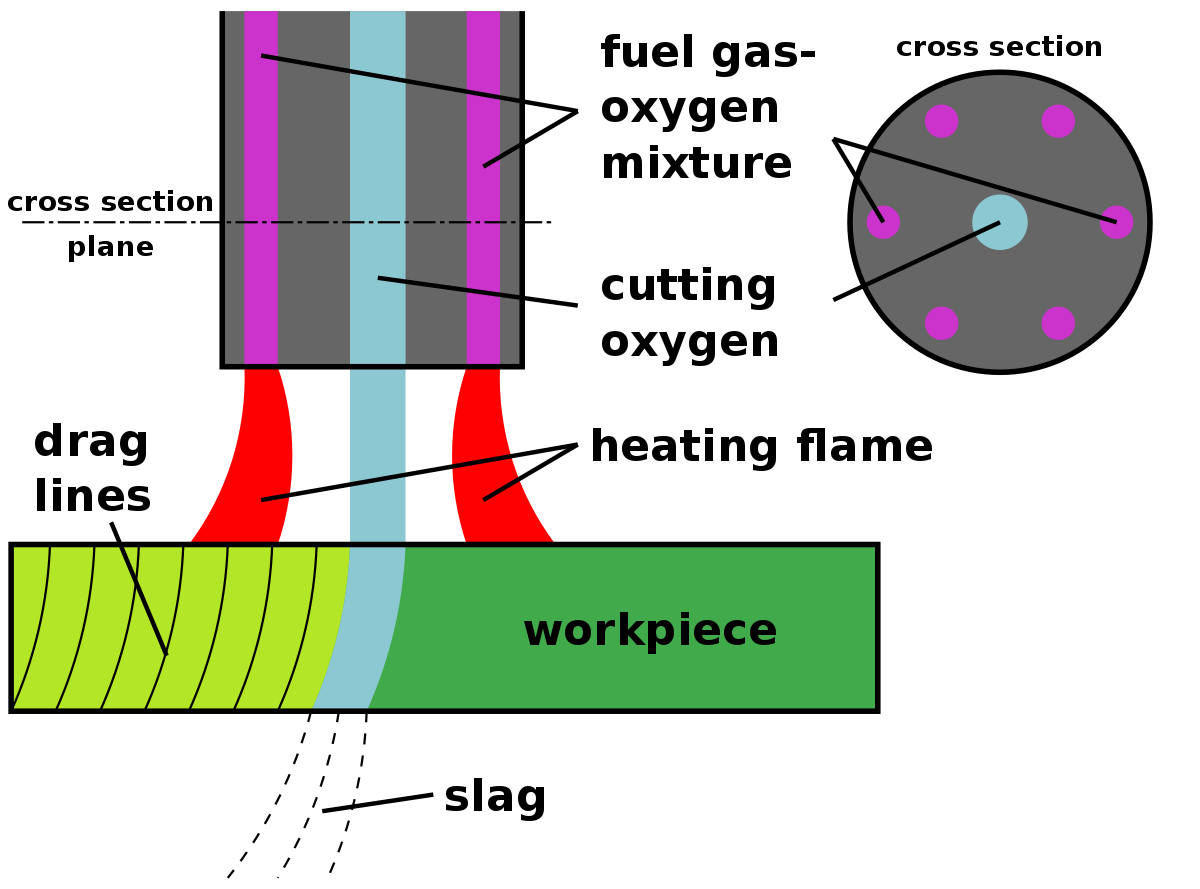

Oxyfuel Cutting

Oxygen fuel cutting, also known as “oxyfuel”, is another process that involves pumping out a gas at high speeds through a thin nozzle to cut a material. The oxygen that is pumped at the metal creates a chemical reaction, which forms iron oxide (a.k.a. “slag”). Oxyfuel does not require electrical currents, so the equipment is generally more portable than plasma. However, the scope of materials that can be cut with oxyfuel is limited to those containing iron. As well as this, gas must be purchased separately in order to maintain use of the equipment. If precision cutting of stainless steel and aluminum is important, then a plasma system is the way to go – plasma provides more accuracy and more reliability than oxyfuel cutting.

If you'd like to learn more, please check out Direct Machine's Plasma Cutting machines or contact us for more information.

https://torchmate.com/white-papers/How-a-plasma-cutter-works

https://mainstaymfg.com/capabilities/plasma-cutting/plasma-cutting-vs-laser-cutting/

https://www.genesis-systems.com/blog/understanding-robotic-fiber-laser-cutting-vs-plasma-cutting