FREE DELIVERY FOR WELDING*

* On Business Days - Purchases $100 or More

2.5% OFF By paying with Check, Wire or ACH

Online and Call-Ahead Orders

* Minimal Purchase Price $100

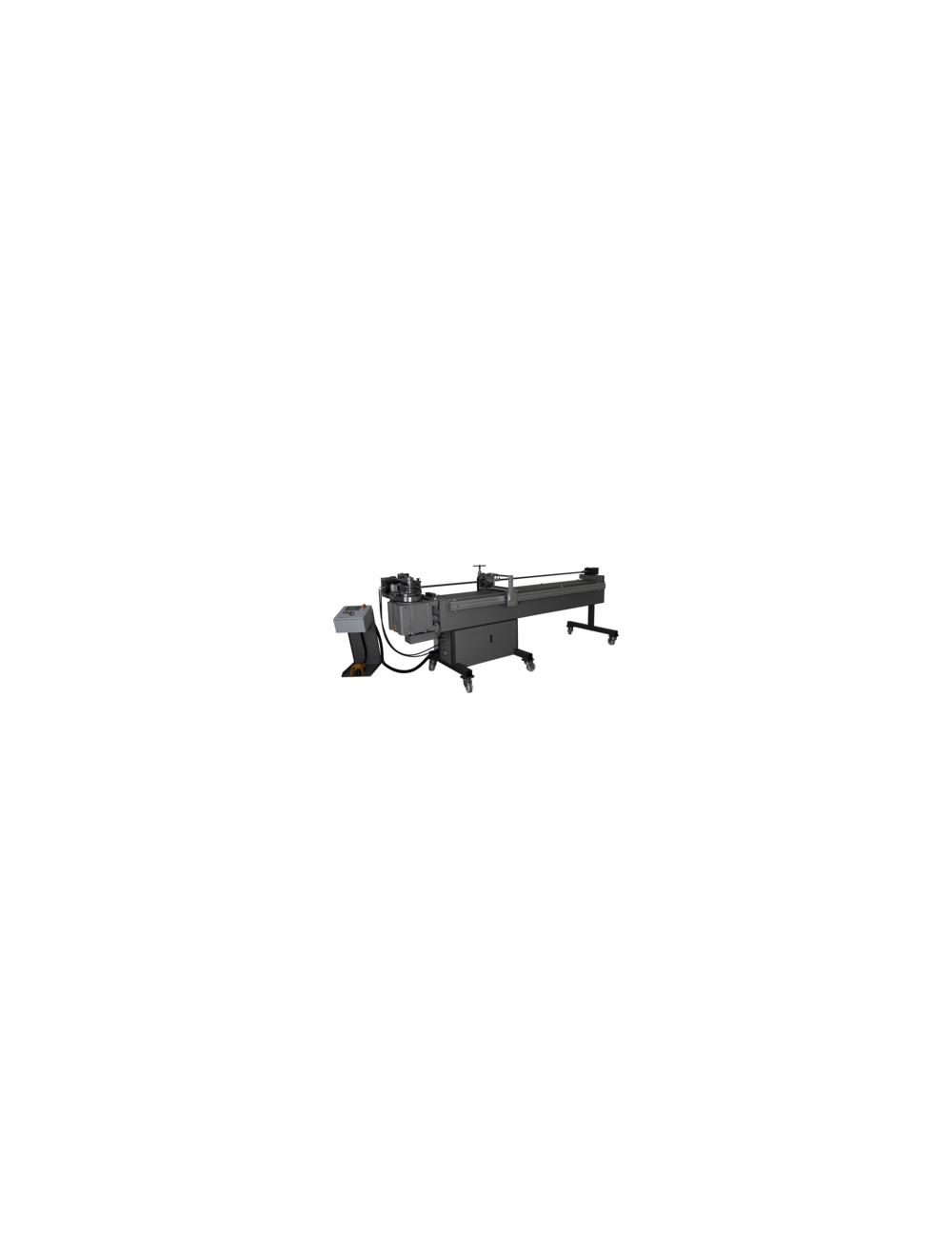

Quantum Machinery Mandrel Rotary Bender with Carriage on Wheels2

The clockwise QMS80 Rotary Bender series is an accurate and powerful Rotary Mandrel Bending Machine capable of bending tubes with a maximum diameter of 3¢â‚¬Â O.D. (76.1 mm) and a pipe thickness of 0.19¢â‚¬Â (5 mm). The maximum bending radius is 7.8¢â‚¬Â (200 mm). The optimal and constant bending radii does not deform bent pipes: it is the ideal machine to satisfy most user requirements in the plumbing, nautical, hydraulic, and ornamental facilities.

CAPACITIES AND TECHNICAL FEATURES

-

Max. Capacity, Mild Steel Round Tube: 3¢â‚¬Â x 0.19¢â‚¬Â (76.1 x 5 mm)

-

Max. Capacity, Stainless Steel Round Tube: 3¢â‚¬Â x 0.110¢â‚¬Â (76.1 x 2.9 mm)

-

Max. Capacity Mild Steel Round Tube: 2-1/2'' SCH. 40 (0.203¢â‚¬Â Thick Wall)

-

Max. Capacity Mild Steel Square Tube: 2.3¢â‚¬Â x 2.3¢â‚¬Â x 0.110¢â‚¬Â (60x60x3 mm)

-

Max. Radius: 7.8¢â‚¬Â (200 mm)

-

Modulus of Resistance: 1.96¢â‚¬Â (5 cm3)

-

Bending Speed (ƒÂ¸/Sek.): 17

-

Repeat Accuracy Bending Axis (ƒÂ¸): +/- 0.003¢â‚¬Â (0.1 mm)

-

Power Output: 7 kW

-

Switch Panel Low Tension: 24V

-

Weight: 3,400 - 4,500 lbs. (1500 - 2000 kg)

-

Bending Direction: Left + Right

-

Bending Speed: 17 Degrees Per Second

-

Bending Accuracy: +/- 0.1 Degree

-

Cast iron body on metal steel-work base.

-

Digital electronic control board with microprocessor and display to set and control the required bend and recovery angle.

-

180° Maximum allowed bending angle.

-

Computerized hydraulic system per the closing and opening of locking and bending tools.

-

The mandrel¢â‚¬â„¢s extraction can be set up for a high definition of the bend.

-

Digital Display of the Length/Torsional Twisting: Standard

-

Premature Mandrel Retraction: Standard

-

Mandrel Lubrication: Optional

-

Revolving Counter-Bearing: Optional

-

Radius Enlargement: Optional

| Shipping Calculation: | All Shipping Costs are calculated after inventory is confirmed with the mfg. |

|---|