FREE DELIVERY FOR WELDING*

* On Business Days - Purchases $100 or More

2.5% OFF By paying with Check, Wire or ACH

Online and Call-Ahead Orders

* Minimal Purchase Price $100

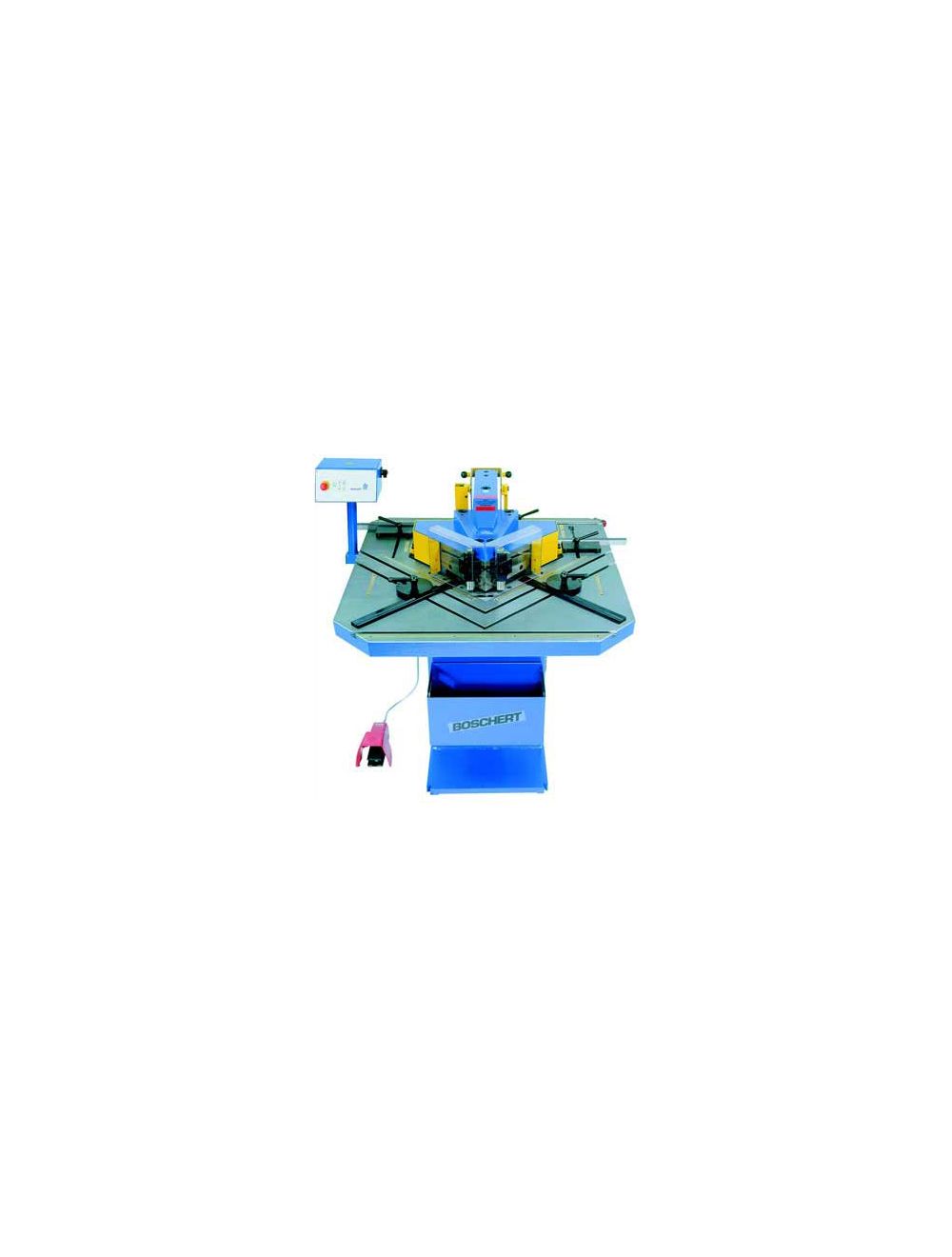

Boschert Silver Eagle Hydraulic Power Notcher

All Boschert notchers offer superior performance, clean cuts and high accuracy. The four notchers in the Silver Eagle series feature Boscherts patented TRI-GIDE technology, a 3-point ram guidance system that gives the machine its world-famous precision and durability.

Description

The Silver Eagle notchers offer 8-7/8 x 8-7/8 90 fixed angle front to back cutting with 1/4in mild steel or 5/32 stainless steel capacity. The 43-inch wide by 31-inch deep super-size table sets the Silver Eagle series apart. The table has a milled bed surface, so materials do not float or stick. The Silver Eagle machines are adjustable from 35 to 50 strokes per minute. They feature an internal stop for shearing, two material hold downs, two heavy duty stops with 12 sliding bars, scale and T-shot left to right at front of bed, scale and T-shot parallel to the blades and scale on left and right side of the tabletop. They are wired for 220v/60c/3ph and feature a moveable electrical foot pedal and scrap buckets.

The Silver Eagle notchers can also be configured with a second station on the rear of the table that can be fitted as either a coping station or a punching station. Alternatively, the Silver Eagle Quick notcher offers a second station that can be changed between punching, coping and notching.

- The Silver Eagle with the coping station has capacities for 5/32 (4mm) mild steel (mild steel designated as 50,000 psi) or 1/8 (3mm) stainless steel (stainless steel is designated as 75,000 psi). It can cope 3.937 deep by 1 to infinity by moving the stock.

- The Silver Eagle with the punching station features Trumpf-style tooling with capacities of 5/32 (4mm) mild steel (mild steel designated as 50,000 psi), 1/8 (3mm) stainless steel (stainless steel is designated as 75,000 psi). Its maximum punch size is 1 1/8 inches. The punching table is 43-inches wide by 13-inces deep.

- The Silver Eagle Quick notcher is equipped with quick-change coping, punching or notching tool sets. The second notching station features 4in blades mounted in a cassette with the correct clearance preset. It has capacities of 5/32 mild steel (mild steel designated as 50,000 psi), 1/8 stainless steel (stainless steel is designated as 75,000 psi). Notch angles can be adjusted from 14- to 45-degree angles.

| Shipping Cost | 0.00 |

|---|---|

| Shipping Calculation: | All Shipping Costs are calculated after order is placed and inventory is confirmed |