FREE DELIVERY FOR WELDING*

* On Business Days - Purchases $100 or More

2.5% OFF By paying with Check, Wire or ACH

Online and Call-Ahead Orders

* Minimal Purchase Price $100

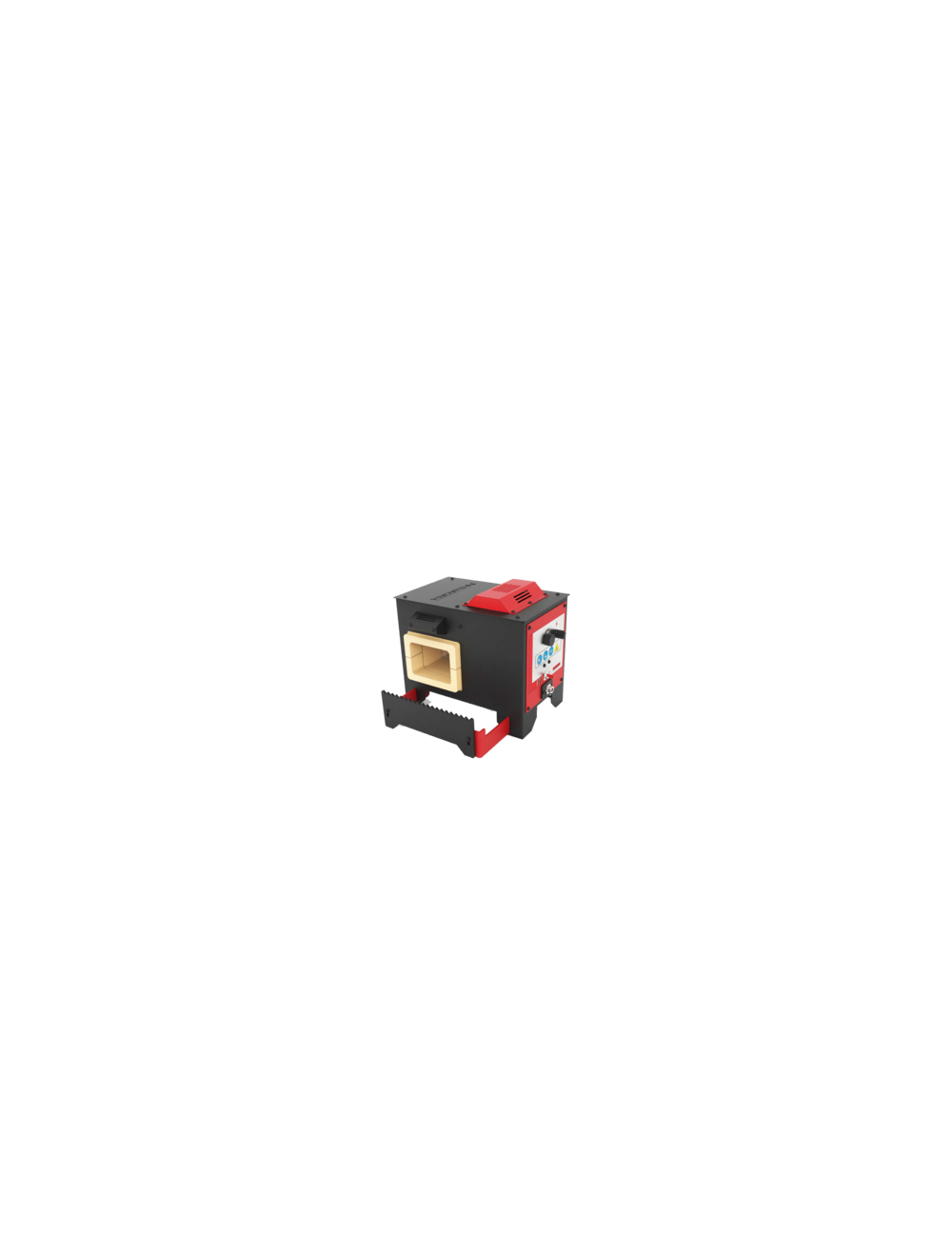

Quantum Machinery INDUSTRIAL PROPANE GAS FORGE FURNACE

The NEWLY Redesigned QUANTUM NARGESA H1 Propane Gas Forge, was designed to heat steel parts. It's used in blacksmith workshops for ornamental forging and molding iron to achieve the desired shapes through end forging, horseshoeing, treatment of parts, etc. It is the greatest substitute for the ancient forge.

Gas Forge Nargesa H1 has one burner.

-

Power (Hi): 4kW

-

Weight: 57 lbs. (26kg)

-

Number of Burners: 1

-

Fuel Type: Propane Gas (GLP)

-

Maximum Capacity: Ø 3.15†(80mm)

-

Maximum Temperature: 2372°F / 1300°C

-

Adjustable Working Pressure: 0.1 - 1.5 BAR

-

Size of Combustion Chamber: 5.5†x 9.25†x 3.9â€Â

-

H1 Forge External Dimensions: 17†x 12.6†x 14.3â€Â

-

Gas Intake as 1 Per Bar x 1 Burner: 0.77 lbs./h (0.35 Kg/h)

-

Removable back door to heat up steel bars pieces in the middle.

-

Combustion chamber isolated by ceramic fiber and refractory brick.

-

Savings with Gas Consumption. Our Propane Gas Forge Furnaces consume less than a 1/4 of the propane used by other furnaces of this type.

-

Extremely Safe, Auto Burner Ignition. Automatic Electronic Ignition ensures that the operator does not need to put their hands inside of the combustion chamber to ignite the furnace.

-

100% Natural & 100% Recyclable Combustion Chamber. The insulation of the combustion chamber is made up of a 100% Natural & 100% Recyclable material, called Vermiculite. The compacted Vermiculite is not harmful to your health or the environment at all - unlike all other gas forge furnaces in the market, which are made up of glass fibers & ceramics, which are extremely harmful to you.

-

Dual Insulation Layer for Heat Effeciency. The Dual Layer of Insulation increases the caloric heating value of our Nargesa furnaces; allowing the furnace to reach temperatures of up to 2370°F / 1300°C inside - while on the outside, the temperature ranges from 86-140°F / 30-60°C

-

There is no fuel loss. All of the gas that enters into the combustion chamber is burned out completely, thanks to Nargesa's patented design of the burners, which have been completely created & manufactured by Nargesa.

-

Stainless Steel, Highly-Durable Gas Hose. Our Gas Forge Furnaces are Equipped with a High-Strength, Extremely Durable Stainless Steel Gas Hose. Generally, conventional Gas Hoses have an expiration date & they must be replaced periodically. Our Stainless Steel Hose never expires and never have to be replaced. Our Stainless Steel Hoses are also Shock and Fire/Heat Resistant.

-

Protected Components. All components are contained within the structured enclosure to eliminate the possibility of damaging any parts, preventing any gas leaks.

-

Large Round Bar Capacity. Our furnaces can heat up round bars up to 3-1/8" (80mm) diameter. There is also a quick-release removable rear door to heat the middle sections of longer pieces.

-

Interchangeable Material Support. Our furnaces are equipped with an Auxiliary Support for the parts being heated. The Support can be quickly adjusted in length and height and has pyramidal teeth to prevent material displacement. You can remove the support and place it in front of whichever opening of the furnace you would like.

-

Next to no Carbon Monoxide Emission Release. Other furnaces have a Carbon Monoxide Emission release of 2%, while our H Series Forge Furnaces have a Carbon Monoxide Emission release of 0.002%, enabling our furnaces to be harmless to your health & the environment.

-

No Possible Leaks. The High Pressure Thermal Couple Safety Valve closes the gas flow when the combustion chamber cools off, due to an anomaly - ensuring that there are no possible leaks.

-

Anti-Return Valve prevents flame from entering into Tank. A Safety, Anti-Return Valve regulates the direction of gas flow, preventing the flame from going back into the cylinder tank. The pressure regulator is equipped with a built-in pressure gauge, allowing the operator to adjust the gas pressure very accurately.

| Shipping Calculation: | All Shipping Costs are calculated after inventory is confirmed with the mfg. |

|---|