FREE DELIVERY FOR WELDING*

* On Business Days - Purchases $100 or More

2.5% OFF By paying with Check, Wire or ACH

Online and Call-Ahead Orders

* Minimal Purchase Price $100

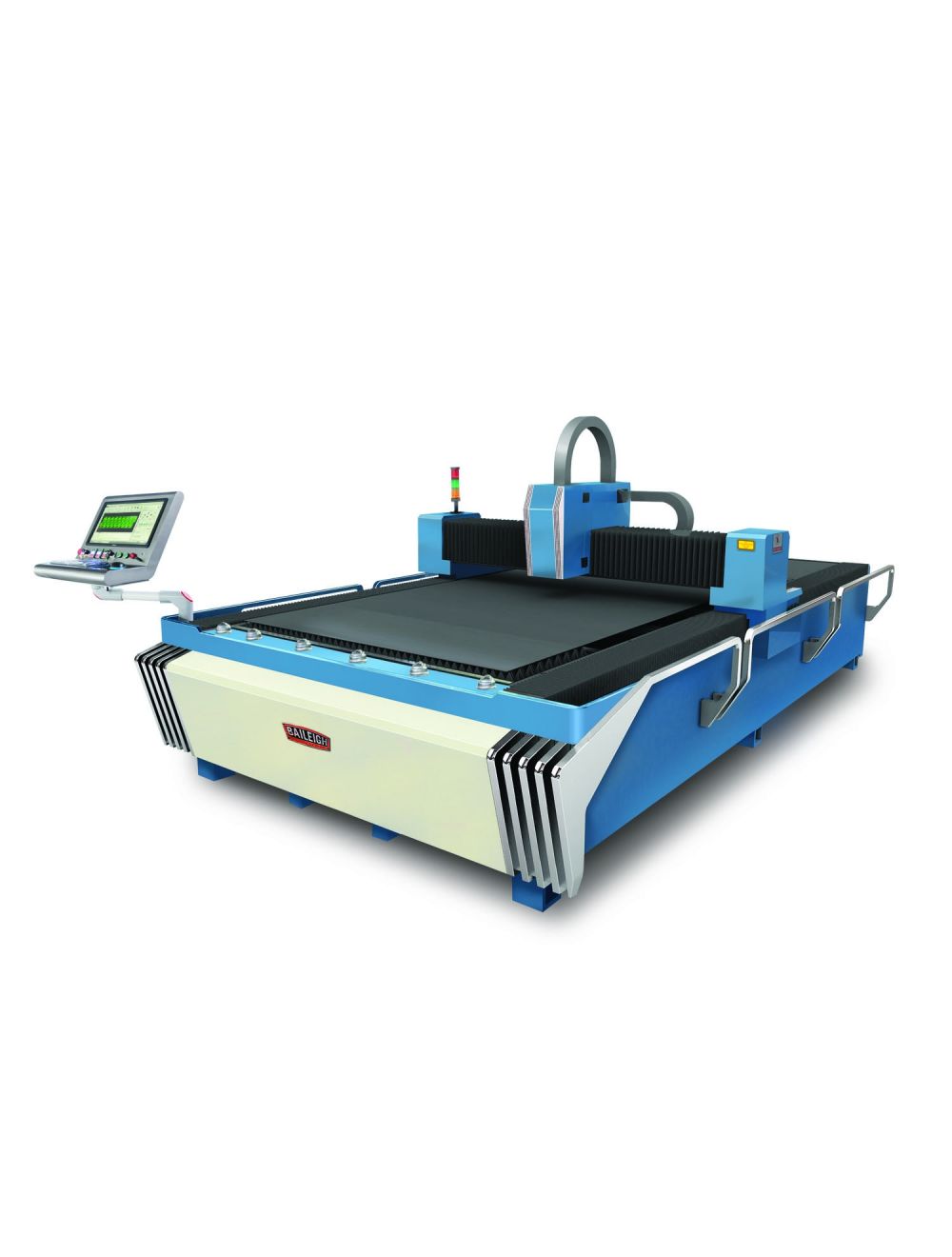

Baileigh CNC LASER TABLE - FL-510HD-500

Our CNC Laser Table - FL-510HD-500 has the structural strength to handle 5' x 10' sheets. This 500 watt fiber laser table is ideal for production runs. It arrives fully assembled and comes with software.

Some features:

- Efficient 500 wat fiber laser Includes chiller- air dryer and exhaust system Runs on 220-volt three-phase power.

- Control the X- Y- and Z axis movement from the sturdy podium with large console screen and keypad. Includes easy-to-learn design software that you can load into any basic PC (more details below).

- Delta brushless servo motors- controlled by Delta servo motion controllers- drive the gantry.

- Industrial-grade gantry travel system for the X- Y & Z axis made from extremely rigid extruded aluminum.

- Gantry can move out of the way for a full 10-foot sheet during loading- minimizing the chance of machine damage.

- High gantry (one of the highest in the industry) lets you clearly see its movement for better adjustment and control. Axes ride on heavy-duty ground and polished square shafts.

- Wiper dies on shafts keep welding dust out of the slide for a smooth transfer without noisy friction caused by dirt build-up.

- Baileigh's design reduces the risk of damaging the table while loading or pinching your forklift.

- CNC laser table weighs an impressive 6600 lbs.

- Fully-welded boxed tubing construction can easily support the weight of maximum capacity material.

- Steel framework will hold its shape and stay accurate for decades- unlike many competitors' aluminum frames- which buckle and warp under heat.

- Pre-built CNC laser table saves you time and effort.

- The alignment is already set up and correct when it arrives.

- Covered by a 1-year parts warranty.

You' ll benefit from lifetime technical support by phone. Call up one of our experienced reps whenever you need troubleshooting.

BOBCAD-CAM EXPRESS DESIGN SOFTWARE (INCLUDED) The CNC Laser Table - FL-510HD-500 comes standard with BobCAD-Cam Express programming software. You can design or plot out your project on any computer and load the laser table via a USB drive.

*Onsite training includes pre-run inspection and operation training for a maximum of 3 days. If more time is needed it will be billed seperately.

Does not include initial placement and set-up of machine.

| Shipping Cost | 1500 |

|---|---|

| Shipping Calculation: | All Shipping Costs are calculated after order is placed and inventory is confirmed |