FREE DELIVERY FOR WELDING*

* On Business Days - Purchases $100 or More

2.5% OFF By paying with Check, Wire or ACH

Online and Call-Ahead Orders

* Minimal Purchase Price $100

PIranha B-Series Plasma Cutting Table MULTIPLE CONFIGURATION PLEASE INQUIRE

INCLUDED FEATURES

1. Rugged Construction – Simple and rugged bolted table with high accuracy linear guides and

bearings. Machine is assembled complete at the factory

2. Dual Side Drive – gantry driven on both sides for maximum stability

3. CNC Control with 10.4” High resolution color LCD monitor, shape library with 20 configurable

shapes, 8MB memory & USB interface

4. Stepper motors and drives – Stepper motors on both X-axis and Y-axis with a maximum traverse

speed of 8000mm/min.

5. Water table slag collection – eliminates need for dust collector.

6. MicroStep Programmable Torch Height Control – controls torch height automatically

7. Breakaway Torch Mounting – protects the torch from inadvertent part tip-ups

8. ProNEST® 2019 LT Programming System – 2D CAD drawing, DXF importing, integrated shape

library, drag and drop nesting.

NOTE: Add-on modules are available for additional functionality of ProNEST® LT

Piranha B-Series Plasma Cutting Tables

Piranha’s latest Plasma Table line introduces an even more affordable plasma table. The Piranha B-Series Plasma Table is perfect for your hobby to light industrial cutting needs. This table retains a lot of the high end features found on the C-Series table and only is short some of the things you don’t need when looking at lighter duty cutting cycles.

- Models:

- Piranha B404 (4’ x 4’ cutting area)

- Piranha B408 (4’ x 8’ cutting area)

- Piranha B510 (5’ x 10’ cutting area)

-

- 510: 158”L x 102”W x 60”H

- Machine Weights:

- 404: 1,300 lbs

- 408: 1,700 lbs

- 510: 2,200 lbs

INCLUDED FEATURES

- Rugged Construction – Simple and rugged bolted table with high accuracy linear guides and bearings. Machine is assembled complete at the factory

- Dual Side Drive – gantry driven on both sides for maximum stability

- CNC Control with 10.4” High resolution color LCD monitor, shape library with 20 configurable shapes, 8MB memory & USB interface

- Stepper motors and drives – Stepper motors on both X-axis and Y-axis with a maximum traverse speed of 8000mm/min.

- Water table slag collection – eliminates need for dust collector.

- MicroStep Programmable Torch Height Control – controls torch height automatically

- Breakaway Torch Mounting – protects the torch from inadvertent part tip-ups

- ProNEST® 2019 LT Programming System – 2D CAD drawing, DXF importing, integrated shape library, drag and drop nesting.

NOTE: Add-on modules are available for additional functionality of ProNEST® LT

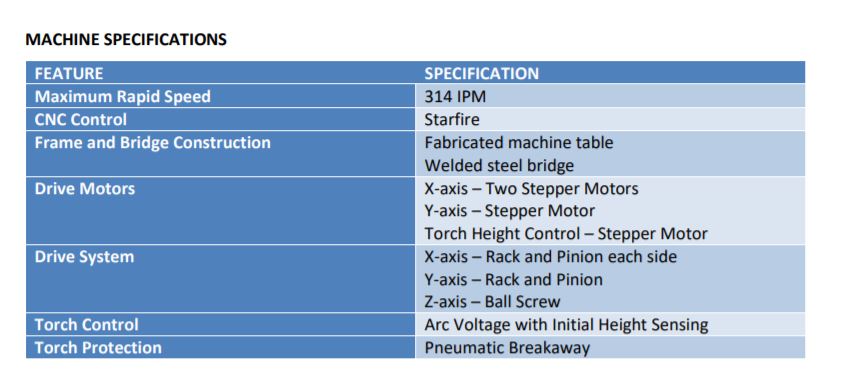

MACHINE SPECIFICATIONS

- Maximum Rapid Speed: 314 IPM

- CNC Control: Starfire

- Frame and Bridge Construction: Fabricated machine table, Welded steel bridge

- Drive Motors: X-axis – Two Stepper Motors, Y-axis – Stepper Motor, Torch Height Control – Stepper Motor

- Drive System: X-axis – Rack and Pinion each side, Y-axis – Rack and Pinion Z-axis – Ball Screw

- Torch Control: Arc Voltage with Initial Height Sensing

- Torch Protection: Pneumatic Breakaway

AVAILABLE PLASMA SYSTEMS**

- Powermax 45XP: 1/2” (12mm) Production / 1/2” (12mm) Maximum (mild steel)

- Powermax 65: 5/8” (16mm) Production / 5/8” (16mm) Maximum (mild steel)

- Powermax 85: 3/4” (20mm) Production / 3/4” (20mm) Maximum (mild steel)

- Powermax 105: 3/4” (20mm) Production / 7/8” (22mm) Maximum (mild steel)

- Powermax 125: 3/4” (20mm) Production / 1” (25mm) Maximum (mild steel)

** Includes interface cable

ProNEST® LT Smart Start (INCLUDED)

Hypertherm ProNest® LT Smart Start is a powerful CAD/CAM nesting software designed for light industrial, mechanized cutting in production environments. It provides a single software solution for all of your conventional plasma cutting machines. ProNest® LT Smart Start helps fabricators and manufacturers increase material savings, boost productivity, reduce operating costs, and improve part quality by offering the right level of cutting expertise for your needs. It also supports Hypertherm SureCut™ technology, including easy setup, optimized process parameters, and easy trouble shooting. In addition, ProNestLT® Smart Start is backed by Hypertherm’s global network of professionals, meaning you’ll always have access to the service and support you need.

Part design and development

- Integrated 2D CAD program to create and edit CAD files

- Variable Shape Parts feature to develop common parts from templates

CAD/CAM import and conversion

- Import CAD files (industry-standard file formats)

- Raster to vector converts static images to CAD

- Automatic CAD file correction and error notification

- Automatic spline/ellipse smoothing and reduction

- Separate multiple parts from a single CAD file

- Automatic mapping of CAD layers to processes (cut, mark)

Job Set-Up

- Material database (with grade and gauge)

- Custom remnant creation (define irregular shapes

- for nesting)

- Grain constraint

- Safe zones for plate clamping applications

SureCut™ technology and built-in process expertise

- Material type, thickness, grade and class-based process parameters:

- Separations for part, plate, and pierce spacing

- Kerf compensation and feed rate

- Lead-in/out style optimized for part geometry and quality

- Cutting techniques

- Cut sequencing – automatic or manual

Interactive manual nesting

- Group parts into clusters for nesting

- Color parts according to part property

- Drag, drop, bump, and auto-bump parts on the nest

- Move, mirror, and drag to rotate parts

- Click and drag to automatically array parts

- Prohibit/permit nesting inside of a part

- Part interference detection

- Edit lead-in/out position and properties within the nest

- Animated cutting sequence simulation

- Control cut direction and cut sequencing on part-by-part basis

- Plate cropping

Detailed reporting

- Management and shop reports

- Export reports directly to PDF, Excel spreadsheet, CSV, or webpage

| Shipping Cost | 0 |

|---|---|

| Shipping Calculation: | All Shipping Costs are calculated after inventory is confirmed with the mfg. |